News

Congratulations on the successful delivery of MV31 of

Shipbuilding Group Corporation!

Praise for Bocheng's comprehensive NDT technical service!

On August 12, the world's largest FPSO project refitted by Dalian Shipbuilding Industry Group Changxingdao Ship Engineering Co., Ltd. was completed. The MODEC MV31 project is currently one of the largest FPSO projects in the world, and the world’s first hull modification MV31 floating production, storage, and offloading service The project is the first module construction and module integration and integration to execute construction in the same shipyard. It is also the heaviest, highest, largest, and most record-breaking project in the current FPSO industry. With a body of nearly 100,000 tons and millions of various components, the volume and complexity of the project are beyond imagination. Qinhuangdao Bocheng Engineering Technology Co., Ltd. is fortunate to have won the trust of the owner, Changxingdao Shipbuilding, and has undertaken this FPSO non-destructive testing technical service project in an all-round way. This is also a professional testing technology service project completed after MV27 with strong professional technology, high project quality and wide application of new technology. The entire inspection process has been supervised and guided by the owner, Changxingdao Ship, ABS Classification Society and MODEC shipowner, and our inspection technology has been highly praised and recognized.

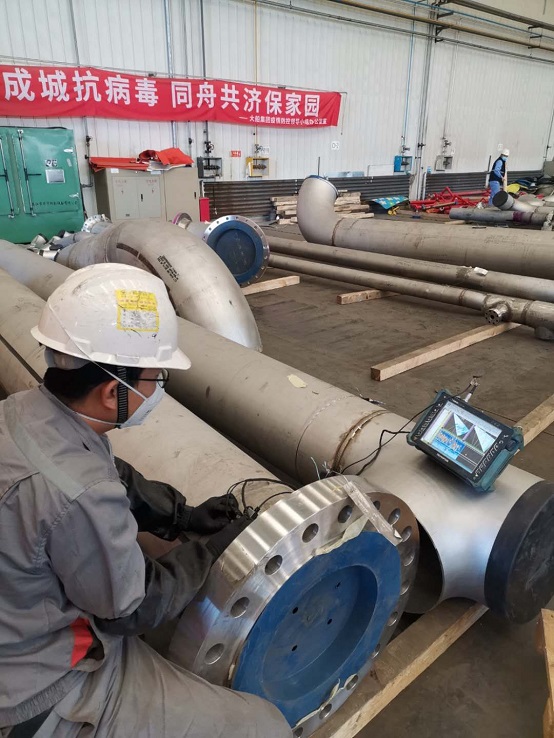

The module construction and module integration of this project involve structures and pipelines of various materials and sizes. The company has done a lot of preparatory work in the early stage, from the training of inspectors to the purchase of advanced imported inspection equipment; from hundreds of comparison test blocks to simulate test blocks The surveyor, shipowner, etc. are required to verify and approve each inspection result to meet the requirements of the norms and standards. Pipeline inspection is the focus of the project. From ordinary carbon steel to stainless steel duplex steel; from wall thickness 3mm to 73mm; from pipe diameter 27mm to 1014mm, each specification and size shall be tested in advance, especially for thicker stainless steel double-phase steel. For the inspection of phase steel, we have done simulation comparison tests to ensure the reliability of the inspection results.

Our testing team with superb testing technology, provide multi-material, full size PAUT technical services. Due to technical limitations or specification requirements, the company also provided a full RT service throughout the project. From each pipe to the completion of millions of various components, PAUT technology and the four conventional testing technologies complement each other and complement each other, solving various testing problems of MV31, overcoming difficulties, and completing various testing tasks with high quality.

After hundreds of days and nights of continuous efforts, we have withstood the test of the epidemic, overcome many adverse factors such as tight construction schedule, heavy task and difficult construction, successfully completed several important nodes, and finally completed the testing task with both quality and quantity. The work has been unanimously recognized by the owner of changxing Island Ship, and set up a good image of the company. Especially, the application of PAUT technology in stainless steel and other special materials has laid a solid foundation for the application of PAUT technology and future development of the company.

Let us maintain the spirit of striving for excellence and indomitable enterprising, and strive to push the company's development strategy to an updated stage, strive to create a new situation, and provide customers with better, more and better services.

copyright 2015 QINHUANGDAO BOCHENG ENGINEERING TECHNOLOGY CO.,LTD All Right Revesved. 冀ICP备15006758号-1